All Casing Construction Methods

-

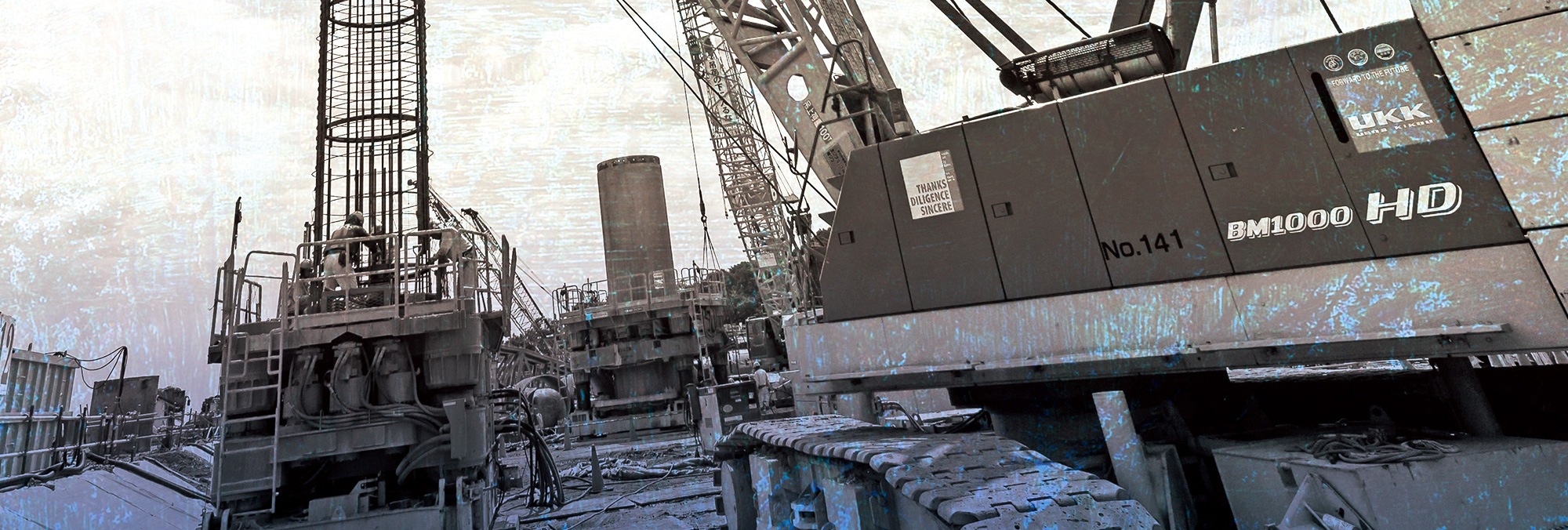

Revolving All Casing Construction Method

Obstacles including hard ground and existing concrete, etc., are easily removed with the large bore and ability to reach great depths.

-

BKF Construction Method(Vibration and noise measures)

Environmentally-friendly drilling technology realizes " low noise and low vibration " in consideration of the neighboring environment.

-

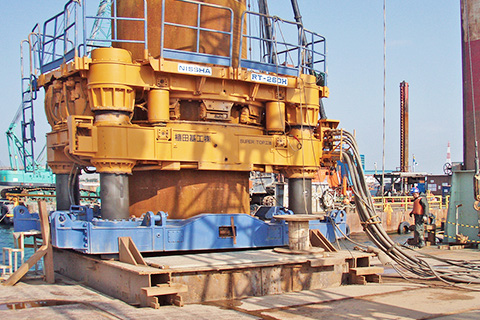

Revolving All Casing Bottom Enlarging Construction Method / GSB Construction Method

Suitable for enlarging the bottom of bedrock. This environmentally-friendly drilling technology incorporates " low-noise, low-vibration " measures in consideration of the neighboring environment.

-

NS ECO-PILE® / Screwed Steel Pile

Screwed steel pipe realizing large vertical holding force and surplus soil free construction

-

Sky Chuck Method(Vibration, noise, hard bedrock measures)

-

MRT Construction Method

Super Drilling Construction Method

(Underground impediment removaland narrow ground measures)

OPTION

Construction Methods for Low Spaces and Narrow Grounds

-

Revolving All Casing Method(Low Space Type)

Easily remove obstacles such as hard ground and existing concrete with the large bore and ability to reach great depths.

-

Micro Revolving Method

Work in narrow spaces and places with low headroom

-

Low Headroom Sliding Method

Work in narrow spaces and places with low headroom

Earth Drilling Method

-

Double Enlarged Bottom Earth Drilling Method / SY Method

The mechanical bucket makes it possible to perform enlarged bottom piling with a 5-fold support force even in narrow places.

-

SB earthquake resistant pile e construction method

Pile head steel pipe wound On-site construction concrete pile